Equi-Flex™ Rod Wiper/ Scraper

What is Equi-Flex™?

Equi-Flex™ rod wiper/scrapers effectively wipe and scrape the full 360° circumference of a reciprocating rod. They are designed to remove road dust, dirt, ice, mud, weld flash, paint and many other particulates from the rod surface. They prevent damage to bearings, seals, packings, and rods, thereby reducing or eliminating contamination of fluids in hydraulic systems.

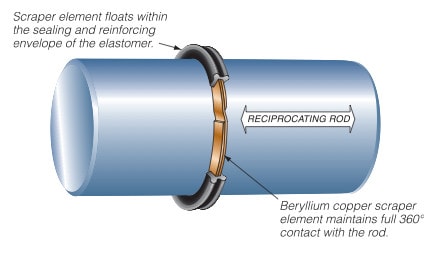

Equi-Flex™ rod wiper/scrapers consist of a honed, double-spiral wiping element of age-hardened beryllium copper (Rockwell C 40 hardness) surrounded by a synthetic rubber elastomer. It is designed so that the beryllium copper element is distended from the final rod diameter. It is precision honed to an inner-diameter tolerance of ±0.0005″. The honing process guarantees a true circle on the ring inside diameter and provides a highly polished and knife-sharp edge. In operation, the beryllium copper ring polishes the rod without damage to the rod’s finish. It is self-sharpening and does not oval, curve, or feather.

Equi-Flex™ rod wiper/scrapers are found wherever hydraulic or pneumatic cylinders are used. They have demonstrated their effectiveness on fork lifts, resistance welders, off-road machinery, farm equipment, hydraulic presses, foundry machines, and aircraft landing gear.

Why Use Equi-Flex™?

Equi-Flex™ rod wiper/scrapers provide the following benefits:

| Feature | Advantage | Benefit |

|---|---|---|

| 360° contact | No gap eliminates clogging and bypasscontamination | Longer primary seal life means more up-time |

| Spring action scraper | Greater rod tolerance | No precision machining of rods |

| Low friction/low wear | Longer scraper life | More up-time & lower equipment maintenance cost |

| Self-sharpening | Continuous and consistent performance | More up-time & lower equipment maintenance cost |

| Occupies a minimum amount of space | Greater design freedom | Smaller package |

| MS28776-R2 compatible gland | Use existing components | No modification required |

| Product availability | Readily available from stock | Reduces design cycle time. Shortens leadtimes resulting in less purchasing and planning |

| Large selection of sizes | Greater design freedom | No non-recurring engineering charges. No custom tooling |

Selecting Equi-Flex™ Rod Wiper/ Scraper Elastomeric Compounds.

Standard Equi-Flex™ rod wiper/scraper elastomers are compounded of a nitrile material which is compatible with most mineral-based oils and other commercial hydraulic fluids within a temperature range of -65°F to 212°F (-54°C to 100°C). However, a wide variety of other elastomers are available to meet special application requirements.

| Letter Suffix | MN Rubber Compound | Shore A Hardness | Compatible With: | Temperature Range |

|---|---|---|---|---|

| A | Nitrile 523EU Date Coded | 70 | MIL-H-5606 Petroleum Fluids Auto Transmission Fluids Water | -65°F to 212°F (-54°C to 100°C) |

| I | FKM 514AD | 70 | Fuel Oil, Chemicals Petroleum Fluids Other Corrosive Fluids | -25°F to 400°F (-32°C to 204°C) |

| P | Ethylene Propylene 559N | 70 | Ozone Aqueous Chemicals Acid or Alkali Phosphate Esters (Skydrol) Auto Brake Fluids | -70°F to 300°F (-57°C to 149°C) |

| None | Nitrile 523EU | 70 | Petroleum Hydraulic Fluids Auto Transmission Fluids Water | -65°F to 212°F (-54°C to 100°C) |

Mounting Principle and Methods

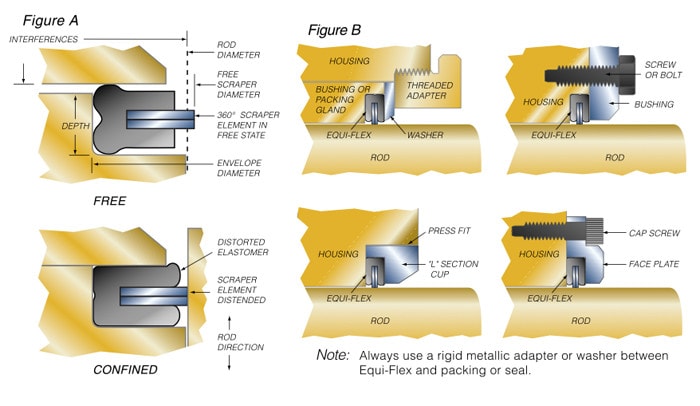

When distended around a rod and mounted in an appropriate recess of proper diameter and depth (Figure A, confined view), the elastomer deforms, surrounds and seals the beryllium copper element in a cushioned suspension. The elastomer prevents solids from migrating through the sealing cavity and reaching the rod bearing or primary seal. It exerts a uniform peripheral squeeze on the wiping element to provide 360° contact with the rod. This squeeze, and the spring characteristics of the beryllium copper element, provide exceptionally good wear resistance for both the scraper element and the reciprocating rod. The elastomer also allows a cushioned float of the scraper element to compensate for normal misalignments.

To obtain the best performance, Equi-Flex™ rod wiper/scrapers should be installed with consideration of the following:

- Equi-Flex™ rod wiper/scrapers should be assembled on the rod in a free state and then confined (Figure A) using gland dimensions from the Housing Recesses Tables PDF.

- To prevent damage to the honed inner-diameter of the Equi-Flex™ scraper ring; A) chamfer the rod ends a minimum of 5° and a maximum of 20°, or B) use a distention sleeve to insert the rod into the Equi-Flex™ scraper. A properly inserted Equi-Flex™ scraper can then be mounted in the housing using any of several mounting methods (including those shown in Figure B).

- Refer to the selection criteria listed above to assure compatibility of the elastomer with the fluids used in your application.

Application Specifications

To assist you in selecting the right materials and part size for your application, include the following information:

- A description of the application including rod length, speed of travel, and materials to be wiped from the rod.

- The type, brand name, product number, etc. for any liquids that may contact the Equi-Flex™ rod wiper/scraper.

- The exact decimal rod size.

- The rod finish and hardness (Rockwell C scale).

- The operational temperature range.

- The service requirements (number of cycles per minute, hour, day, etc.).

Rod Diameters

Equi-Flex™ rod wiper/scrapers are distended on an arbor and honed to 0.005″ under the normal rod diameter. They may be applied without modification to rods that are 0.003″ larger or smaller than their nominal diameter. If a rod diameter exceeds the honed diameter of an Equi-Flex™ wiper by more than ±0.003″, special honing may be required to ensure effective 360° wiping performance.

Friction

The friction experienced by an Equi-Flex™ rod wiper/scraper is primarily determined by the diameter and depth of the elastomer retaining cavity. Standard cavity dimensions ensure tight wiper contact with the rod while maintaining relatively low friction. If an application demands a minimum of drag force, the cavity dimensions can be modified and we can add a special polishing procedure.

Rod Finish and Hardness

Standard Equi-Flex™ rod wiper/scrapers function best on rods having a surface finish of 25 micro inches RMS or better. The rod should be chrome-plated or hardened to Rockwell C 45 or harder.

Elastomer Compounds

Standard Equi-Flex™ rod wiper/scrapers consist of elastomers made from a 70 Shore A nitrile material. This material is compatible with most mineral-based oils and other commercial hydraulic fluids. A wide variety of custom elastomer materials is available to meet special application requirements. Commonly used materials and associated physical properties are shown in the table on the proceeding page.

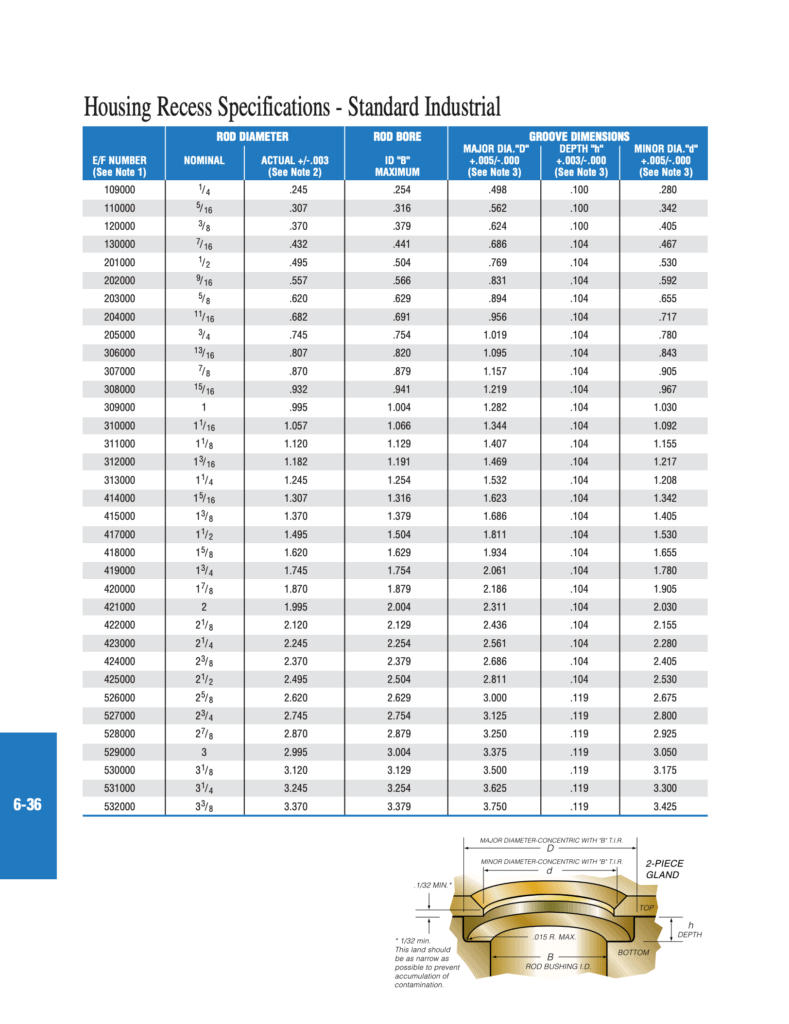

Housing Recess Specifications

Click below to view the Housing Recess Specifications PDF