Innovative, custom solutions

Meeting your quality and application requirements

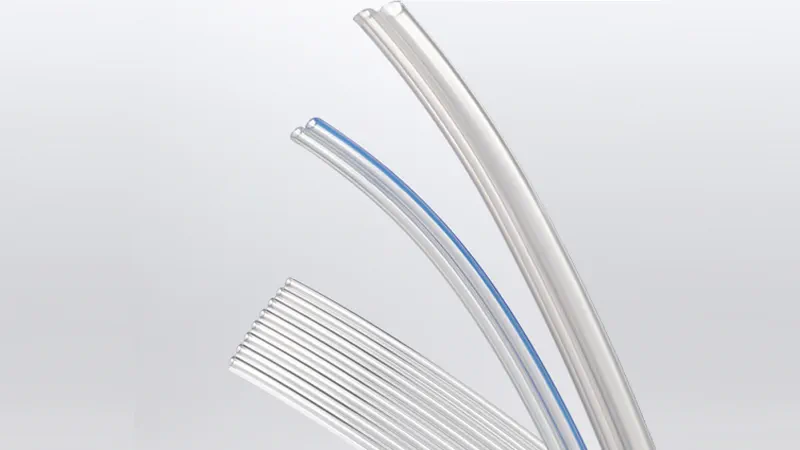

Trelleborg Medical Solutions develops, manufactures and supplies tubing & hose for medical and pharmaceutical applications in a variety of high performance materials. The tubing and hose is extruded in clean-room facilities using Good Manufacturing Practices (GMP).

Silicone tubing, because of its unique biocompatibility and physical durability, plays a fundamental role in a myriad of healthcare applications. Inside the body it is used as insulation on electrical stimulation devices, as conduits for delivering and removing fluids, and as catheters for various types of interventional therapies. Outside the body it is ideally suited for applications including blood oxygenation as well as many pharmaceutical manufacturing processes.

Case studies in applying advanced extrusion technologies for medical device design

Find out how the GeoTransTM extrusion process can support the design of intricate and complicated medical devices.

Tubing & Hose Products

Tools & Literature

Fighting Hospital Acquired Infection

Exploring methods of combining silicone tubing with APIs

Application Examples

Bioprocessing Flow Tubing

Customer: Bioprocessing Equipment Manufacturer

Application: Bioprocessing Flow Tubing

Issues:

- Desired flow rates not being achieved

- Tubing collapsing due to large suction pressure from rotary lobe style pump

Solution

- Tubing wall was increased to 0.48 mm / .188 inch from 0.32 mm / .125 inch while maintaining the same inner diameter.

- The customer required a high flow rate discharge due a large volume bottom outlet disposable biobag. This involved switching from a peristaltic pump to a rotary lobe style pump. Thicker wall tubing prevented the tubing from collapsing and the specified flow rates are being met.

Central Vascular Access Catheters

Components For Disposables

Customer: Catheter Manufacturer

Application: Multi-lumen tubing and liquid injection over-molding connectors for Central Vascular Access Catheters

Issues:

- Maintaining orientation of feeding lines

- Cleanroom production require

Solution

- Multi-lumen tubing and overmolded connectors utilizing combined high-precision liquid injection molding and extrusion production techniques

- Gish Biomedical of Rancho Santa Margarita, California, awarded Trelleborg Sealing Solutions Northborough a contract to produce multi-lumen tubing and liquid injection over-molding connectors for their Central Vascular Access Catheters. The award was based on our years of experience within the life science market producing high quality engineered solution