Pawling Engineered Products

Custom Rubber Products Engineered to Meet Your Exact Specifications

Minnesota Rubber & Plastics is pleased to include the Pawling Engineered Products product line in our suite of custom elastomeric solutions.

The Pawling Engineered Products product line includes a wide range of highly engineered elastomer products, including inflatable seals and clamps, custom compression seals, gaskets, tubing, extrusion, and other elastomeric fabrications designed for critical and demanding applications.

These products are designed to meet customers’ exact specifications and are able to withstand the rigorous requirements of the world’s leading original equipment manufacturers.

Innovative Solutions for Critical and Demanding Applications

Our ability to devise innovative solutions, and our responsiveness, flexibility and willingness to tackle customers’ tough application challenges – from very practical to highly-complex applications – is what sets us apart.

Pawling Engineered Products Line

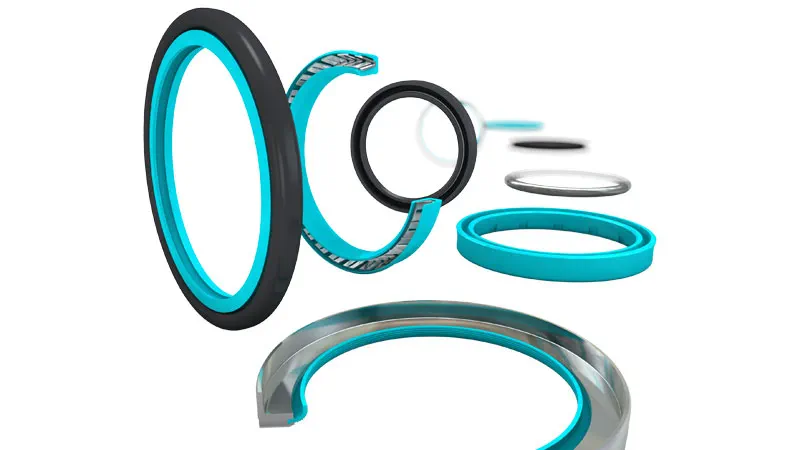

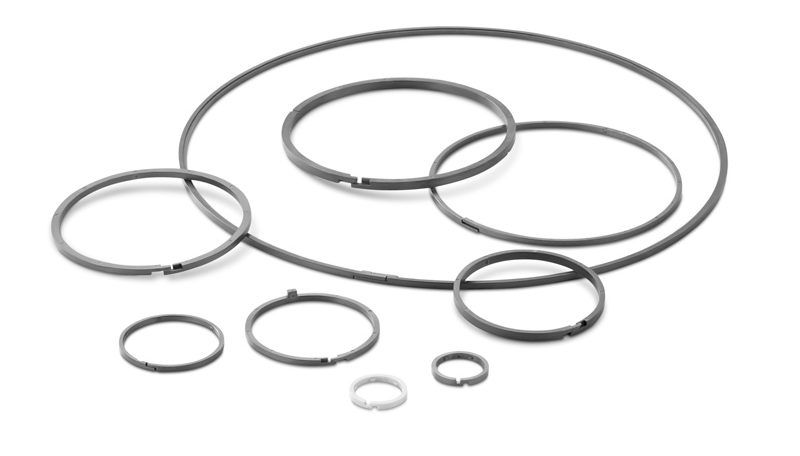

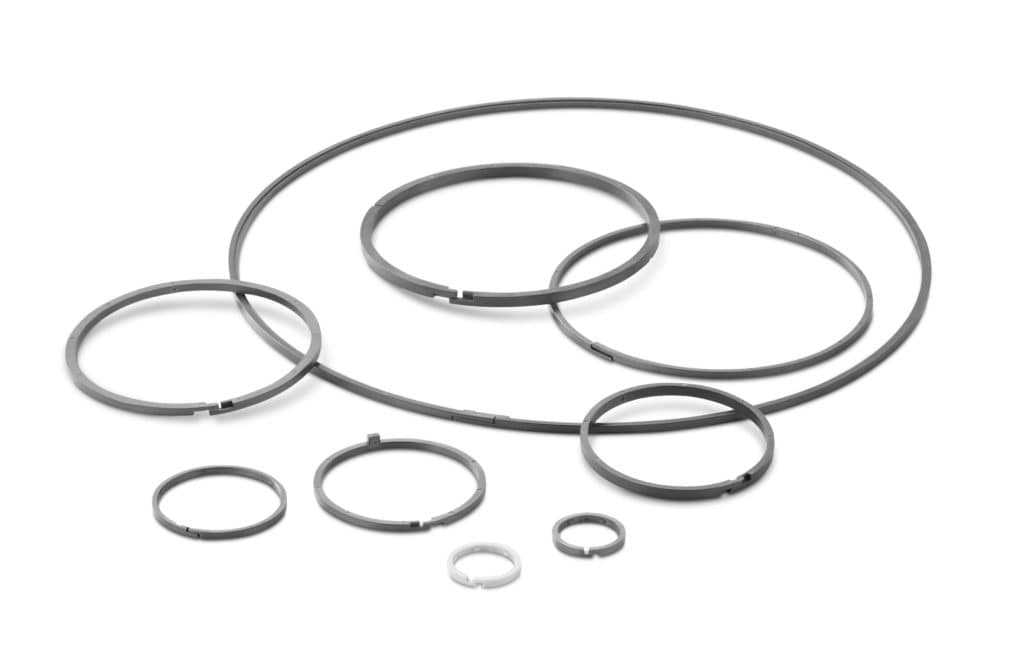

Inflatable Seals

Our inflatable seals create an air or watertight barrier. They require less force to ensure a good seal – just move the mating parts into place and inflate the seal to close the gap. This makes them the perfect solution for unique and/or difficult sealing applications.

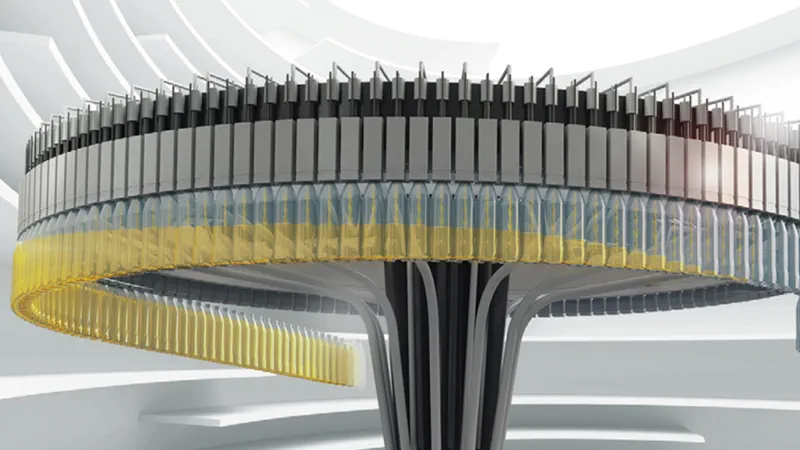

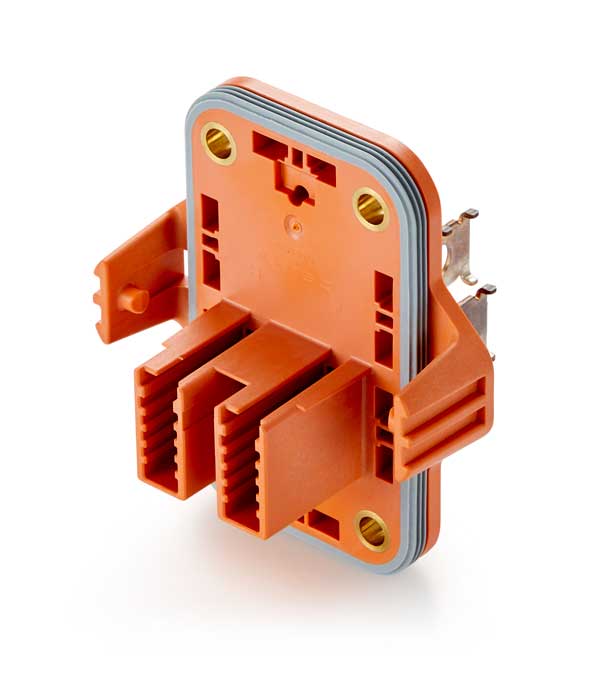

Inflatable Clamps & Actuators

Inflatable clamps provide uniformed controlled pressure to firmly clamp or bond products together. Inflatable actuators are used to push a secondary seal (or fixture) into place in order to create a uniform, reliable seal. Let our years of experience in the design and manufacture of unique clamping and actuating solutions work for your application.

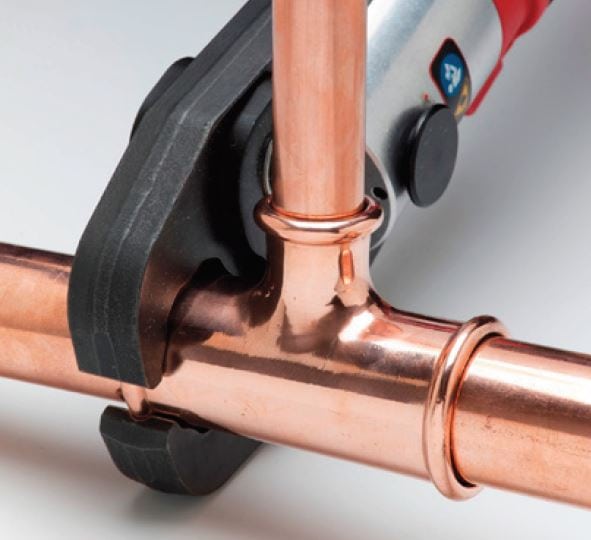

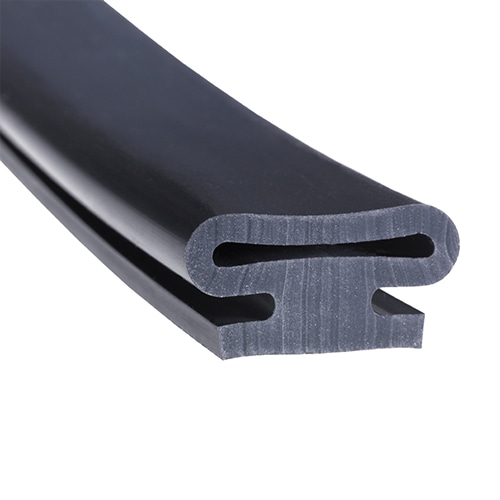

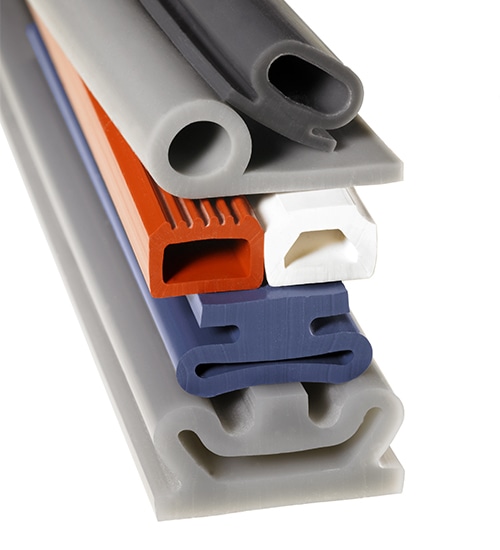

Compression Seals & Gaskets

We have full capabilities of designing and manufacturing custom elastomeric compression seals, gaskets, tubing, and bumpers. They can be configured to any shape or size depending for your unique application. Compression seals can be simple round shapes or highly complex designs with square corners and fastening holes.

Septa

See our line of silicone septa closures that suit a variety of applications – from environmental bottle liners to HPLC and GC vial septa. Only the highest quality silicone elastomers are used to ensure proper reseal-ability and to minimize coring.

Looking for Technical Information?

See information on how seals are constructed & designed, inflatable sealing gaps, profile constructs, how extruded parts can be finished, corner and end details, available air connector types, and the various material configurations. All details can be found in the MN Rubber Design Guide.

Quick Resource Links:

Applications

Through the addition of the Pawling Engineered Products product line, we have widened our scope of solutions.

Have a sealing challenge?

Design Engineers: Read our Design Guide

To gain a better understanding of the processes, materials and technical considerations involved in the design and manufacture of custom-molded rubber, read through our Engineer Design Guide. This comprehensive design tool details both rubber and plastic design issues including a materials overview and prototype mold design considerations.