Expert Company in Rubber Molding, Plastics Manufacturing and Assemblies

Our rubber and thermoplastics molding company specializes in developing and manufacturing custom-molded rubber and thermoplastic components + the integration of both in complex assemblies.

When our company’s clients are facing tough molded rubber and thermoplastic engineering challenges, they turn to us early in a project for our material science, design support, and manufacturing expertise.

The result: quick answers, multiple options and long-term project success. With our organization’s science-based approach to solving problems, we specialize in designing and manufacturing close-tolerance components and assemblies that must comply with stringent federal regulations such as FDA Class 1, 2 and 3 products.

Custom Molded Rubber Manufacturer

Minnesota Rubber and Plastics is a leader in providing precision molded rubber components.

Throughout our global operations, our focus is on creating value for our customers by providing outstanding technical and manufacturing services. From design and materials engineering to customer support, we demonstrate our commitment to excellence in the quality and performance of the products we sell.

Custom Liquid Silicone Rubber (LSR) Injection Molding

If you’re looking for a proven design to manufacturing resource for your custom LSR projects, we have you covered. LSR is among a large portfolio of elastomers our customers spec for projects requiring unique properties.

From designing, prototyping, tooling management, manufacturing, and distribution, we comply with all regulatory guidelines, including ISO 13485 and 21CFR820.…

Custom Molded Plastic Manufacturer

As a manufacturer of high precision thermoplastic components, Minnesota Rubber and Plastics specializes in finding solutions to tough applications which require the molding and assembly of close tolerance components.

We offer a wide range of technical services and production capabilities for producing close tolerance injection molded plastic components, assemblies and sub-assemblies.

Over-Molded Solutions Manufacturing

We provide state of the art rubber and plastic over-molded solutions as well as plastic – plastic, plastic – metal, and rubber – plastic bonding.

The ability to combine these materials for an integrated solution saves time and cost while enhancing overall performance.

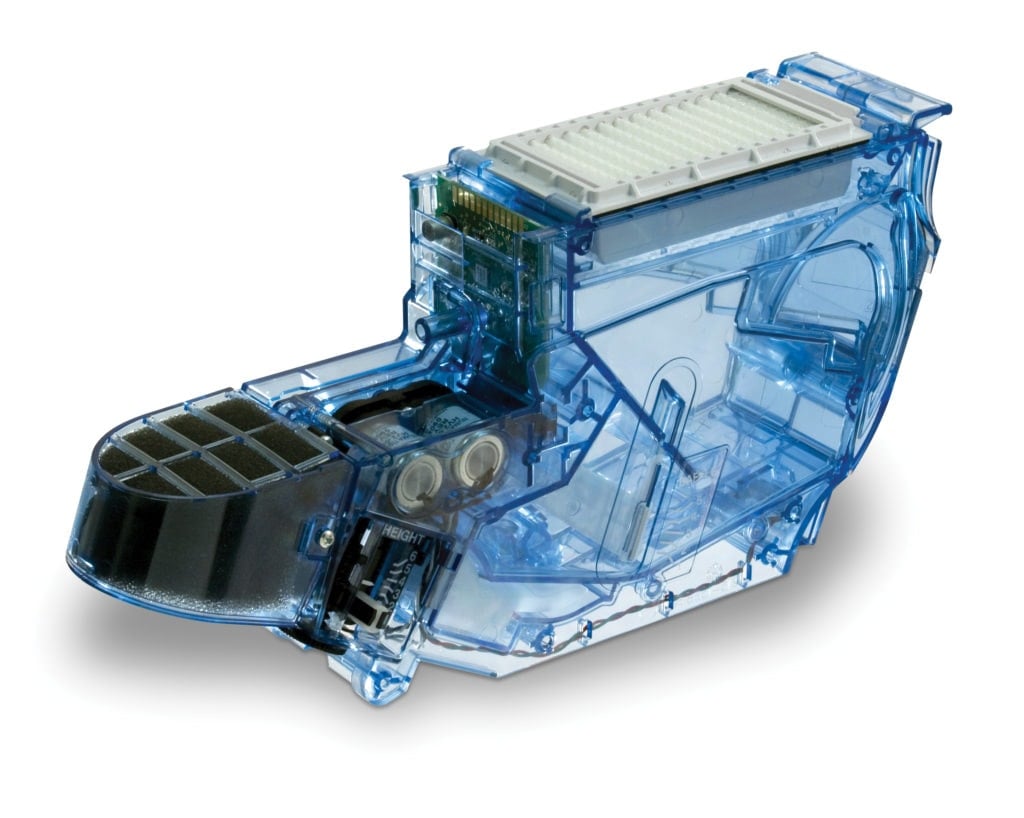

Assemblies

Combining our industry leading rubber and plastic molding capability with state of the art assembly and quality systems to enhance the overall value we bring to our customers.

From complex medical device assemblies in an ISO certified clean room environment, to highly automated transportation applications, we are sure to have the value added assembly solution to fit your needs.

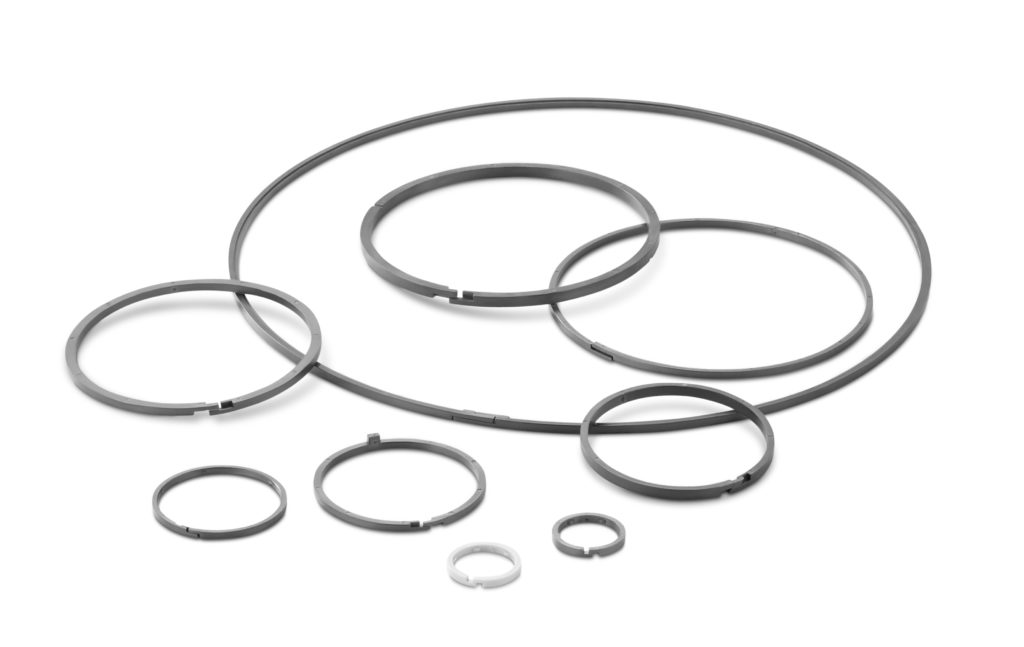

Standard Products

Minnesota Rubber and Plastics produces a complete family of Standard O-Ring, Quad-Rings® seal Brand and custom seals to provide the optimum seal for a wide range of applications.

Our original four-lobed Quad-Ring® seal Brand design has been expanded into a complete line of custom seals with unique features to handle the most difficult sealing requirements

Inflatable Seals and Gaskets

Minnesota Rubber and Plastics Develops and Manufactures Custom Inflatable Seals and Gaskets for any Application.

When compared to elastomeric compression seals, inflatable rubber seals are more forgiving of irregular or misaligned surfaces, which boosts sealing integrity.

Our inflatable seals are being used today in environments where cleanliness and containment are paramount.

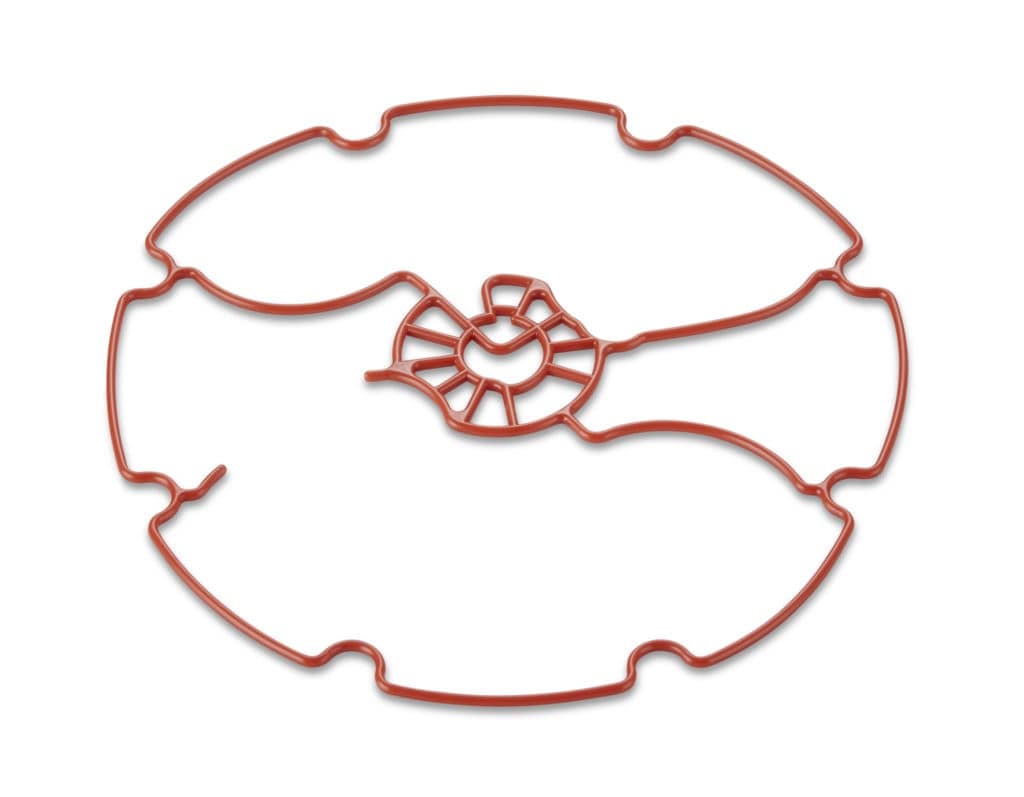

Compression Seals and Gaskets

Our products have full capabilities of designing and manufacturing custom elastomeric compression seals, gaskets, tubing, and bumpers.

Compression seals can be simple round shapes or highly complex designs with square corners and fastening holes. Many different materials may be used depending on the application.