Automotive

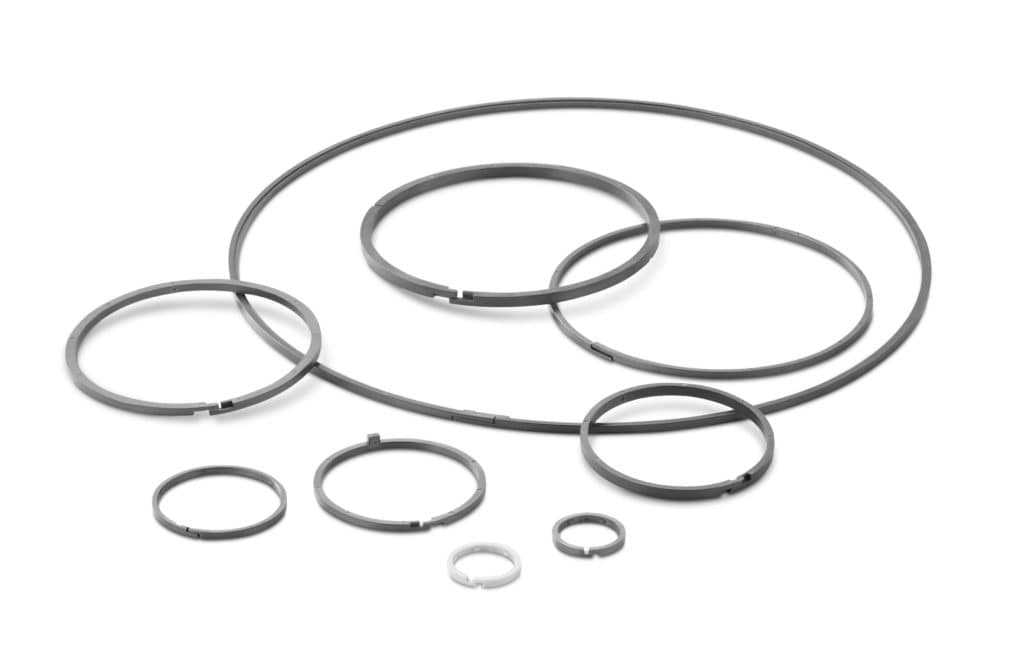

When friction, sealing, dimensional stability and wear are crucial, rely on us. Whether high-performance plastic or custom-molded rubber, we’ll deliver the high-quality seals, thrust washers, and other critical-to-function components your system needs to run smoothly and efficiently.

We engineer and manufacture thousands of precision-molded components and assemblies for automotive applications. Our experienced engineers and technicians will work closely with you to design, test and manufacture the tight-tolerance parts for ePowertrain, hybrid and EV powertrain systems and other vehicle system applications.

View all Automotive Applications

A Broad Spectrum of Services and Capabilities Save you Time and Costs

To help you create custom solutions that’ll solve any automotive engineering challenge, we offer a broad spectrum of services and capabilities from a single source:

Applications

Minnesota Rubber & Plastics engineers and manufactures thousands of precision components designed for automotive applications. Explore several applications below:

Need help solving a tough engineering problem?

Case Studies

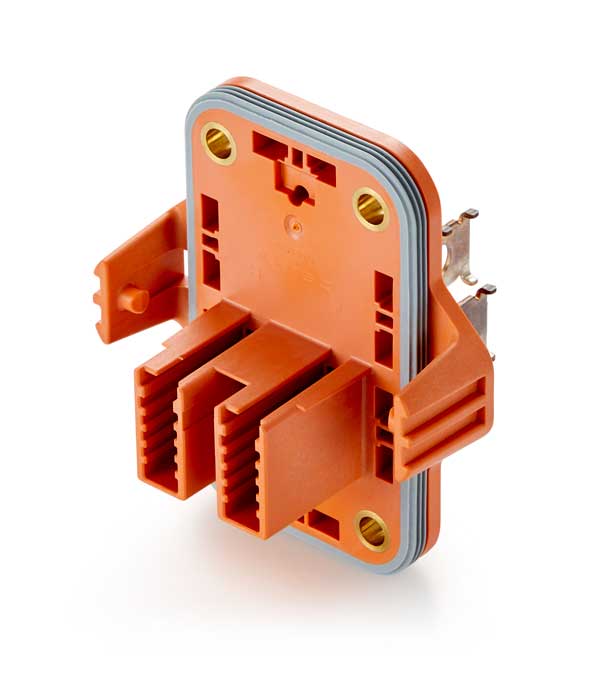

How Assembly Design And Manufacturing Improves Products

Engineered components, when combined into assemblies, can advance a product’s performance as they have in today’s highly efficient and reliable automobiles. New standards are set when individual components are redesigned into more efficient assemblies leading to vastly improved performance. Such is the case with vehicles of all types as most components such as shock absorbers redesigned of new, lighter materials last longer and are more cost effective to manufacture.

How Over-molding Improves Product Performance

Creating molded rubber parts with inserts involves considerable preparation before and after molding. These tips can help ensure a durable finished part while minimizing production costs.