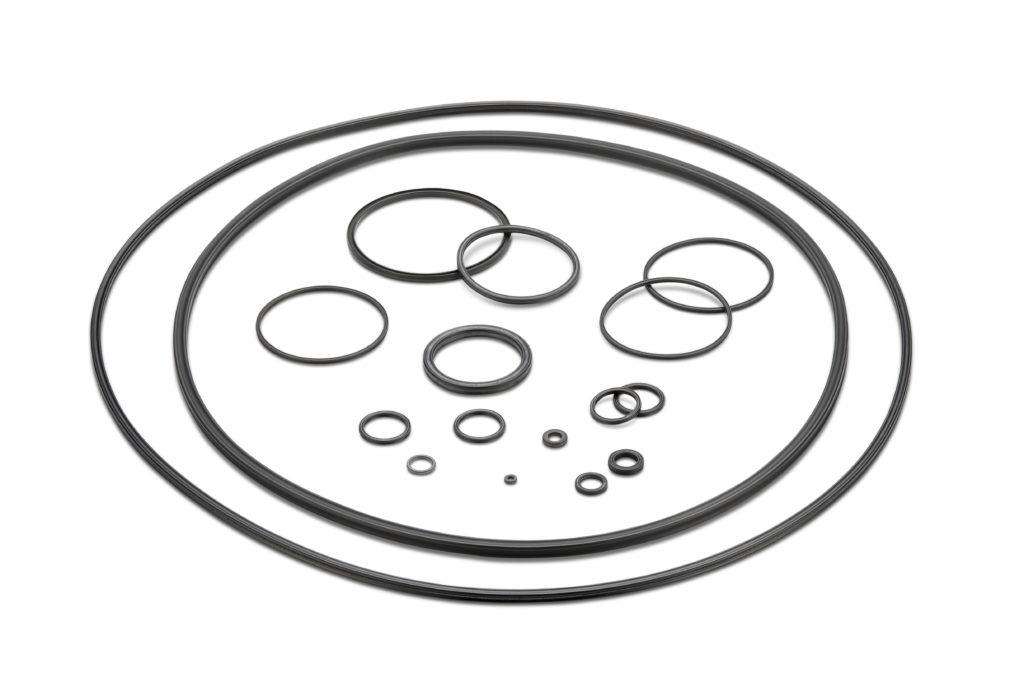

Standard & Quad® Brand Products

We are the originators of the Quad-Ring® seal design and offer a full line of sealing solution options in our standard product offering.

Minnesota Rubber & Plastics, now Trelleborg, produces a complete family of standard O-Ring, Quad-Ring® Brand seals and custom seals to provide the optimum seal for a wide range of applications.

Our original four-lobed Quad-Ring® Brand seal design has been expanded into a complete line of custom seals with unique features to handle the most difficult sealing requirements.

Quad-Ring® Brand Seals

The original Quad-Ring® Brand seal is a four-lobed seal developed to prevent spiral twist and withstand distortion and extrusion.

As the original patent holder since 1959, Minnesota Rubber & Plastics is recognized as the novel Quad-Ring® manufacturer, a product known as the solution for complicated applications where enhanced performance is critical.

Benefits

- Longer seal life

- Reduced friction

- Eliminates leakage with sealing surfaces placed strategically away from parting lines

- US-Engineered

- Near shoring and global manufacturing help to eliminate supply chain issues.

- Lower failure rate as compared to alternative products such as x-rings.

- Well-suited for static, reciprocating and oscillating seals.

Standard Material Types used for Quad-Ring® Brand Products

- NBR: 366Y

- FKM: 514AD

- EPDM: 559PE

Learn about the Quad® Brand Seal Family:

Have a tough engineering challenge that calls for a standard seal solution?

Identifying A Sealing Application Type

Although sealing applications can be classified in many different ways, a common method for classifying sealing applications is by the type of motion experienced by the application. The common application types are depicted in our online design guide. Plus, general sealing principles common to all of the seal types are discussed. View our online design guide.