Infrastructure Rubber and Plastics Component Manufacturing & Assembly

Component design and materials knowledge for demanding applications.

The infrastructure market demands manufacturers have a deep knowledge and understanding of all-encompassing end-market applications. The market also requires component design and materials-knowledge for products that function without failure, in demanding applications.

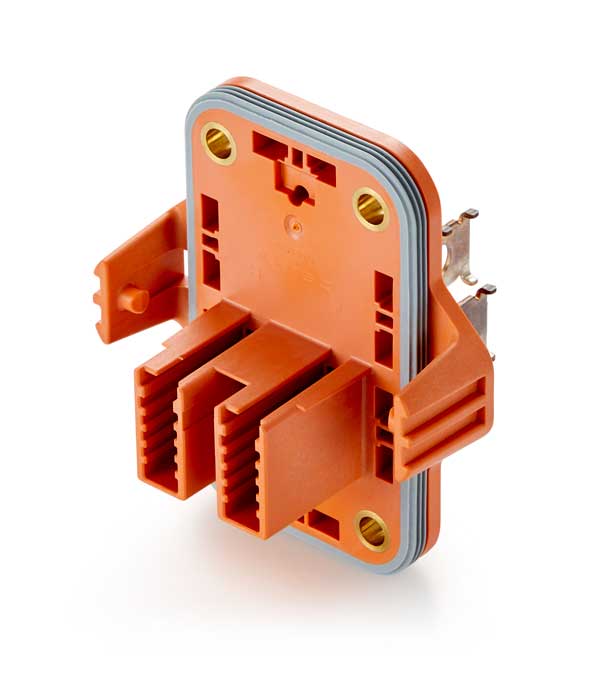

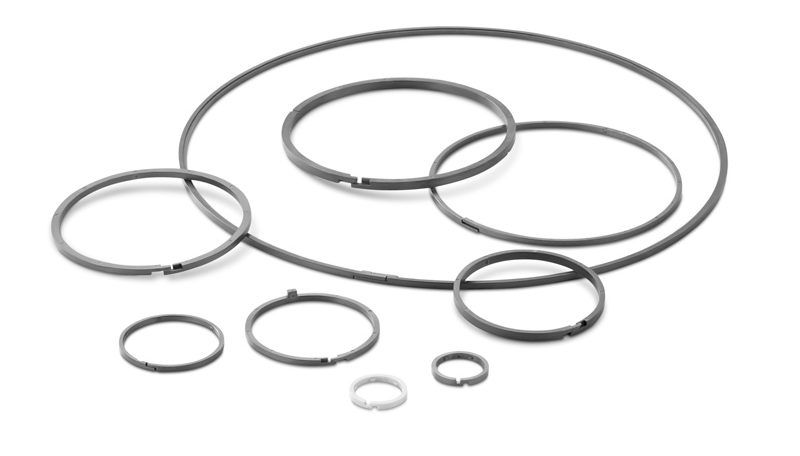

Minnesota Rubber and Plastics (MRP) is uniquely positioned to offer both rubber and plastic combination parts for infrastructure applications. This allows us to provide greater development and production efficiencies, thereby reducing development time and costs. From prototyping to final production, our advanced materials science and design engineering services provide timely answers to difficult design questions.

Infrastructure applications require speed-to-market and low failure rates. Infrastructure organizations turn us to solve difficult engineering and materials science challenges, and they can rely on us to create production intent prototypes that ensure the components in their design can perform from day one, and for the long haul, with significant manufacturing volume scale. Learn more about our innovation center – the hub of our new product development collaborations with customers.

For static and dynamic applications, our expertise in engineering design, materials science, manufacturing and assembly has made us the preferred supplier for infrastructure original equipment manufacturers (OEM) around the globe.

A Broad Spectrum of Services and Capabilities Save you Time and Costs

To help you create custom solutions that’ll solve any infrastructure engineering challenge, we offer a broad spectrum of services and capabilities from a single source: