Water, Food & Beverage

From proposal, through design to delivery, we take your business as seriously as we take our business of molding advanced, critical-to-function parts. We offer custom material formulations, and a complete selection of water, food and beverage certified compounds.

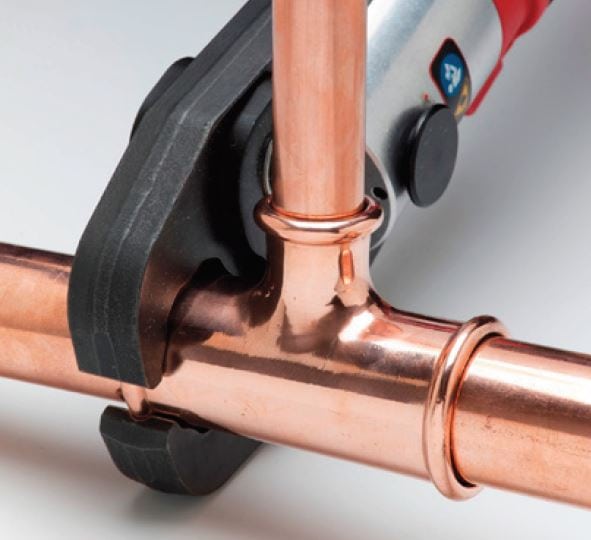

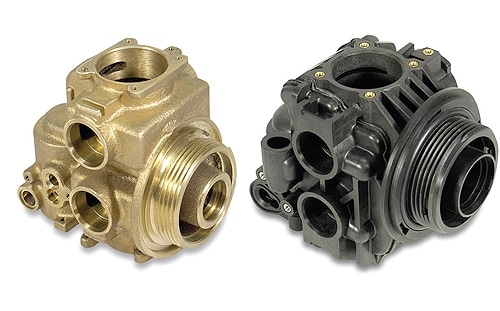

Our engineers and technicians formulate materials, design, manufacture, and assemble components made from rubber and high-performance thermoplastics. Design engineers turn to us to help them build solutions for drinking water filtration and treatment applications, beverage dispensers, press/push fittings, water heaters, plumbing fixtures and more.

Minnesota Rubber & Plastics is now a part of Trelleborg

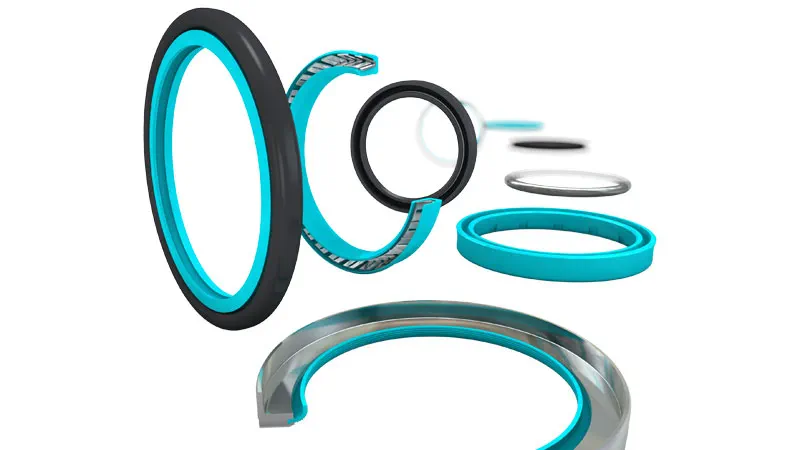

Trelleborg Sealing Solutions is one of the world’s leading developers, manufacturers and suppliers of precision seals, bearings and custom-molded polymer components for the water, food and beverage industries. With our global footprint, we provide customers with exceptional innovation opportunities for technically demanding applications in the areas of drinking water filtration and treatment applications, beverage dispensers, food and beverage processing, water irrigation, water heaters, plumbing fixtures and more.

Seals must meet regulatory requirements while improving productivity. They must be compatible with different food types and ingredients, such as fats, oils and acids. In addition, hygienic design and resistance to cleaning media are top priorities. By forming collaborative partnerships, we help design, develop, manufacture, and bring high-performance solutions to help meet the most challenging compliance and efficiency demands.

The combined expertise of Minnesota Rubber & Plastics and Trelleborg provides customers with exceptional innovation opportunities. We provide advanced solutions in materials science and formulation, fully functional product prototyping, and operational excellence and supply chain consolidation.

Find more information about how Trelleborg Sealing Solutions supports customers with innovative solutions for the water, food and beverage industries, here.

A Broad Spectrum of Services and Capabilities Save you Time and Costs

To help you create custom solutions that’ll solve any water, food and beverage engineering challenge, we offer a broad spectrum of services and capabilities from a single source:

Applications

Minnesota Rubber & Plastics engineers and manufactures thousands of precision components designed for water, food and beverage applications. Explore some of these applications below:

Now Part of Trelleborg

Trelleborg Sealing Solutions is one of the world’s leading developers, manufacturers, and suppliers of precision seals, bearings and custom-molded polymer components for the water, food and beverage industry. With our global footprint, we provide customers with exceptional innovation opportunities for technically demanding applications in the areas of drinking water filtration and treatment applications, beverage dispensers, water irrigation, water heaters, plumbing fixtures and more.

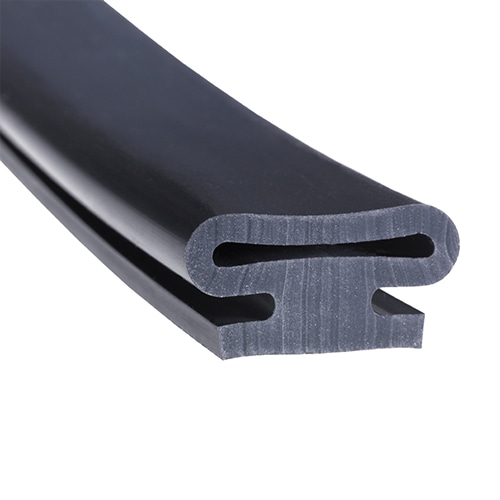

- Food Processing Inflatable Seals

- Industrial Beverage Dispensing

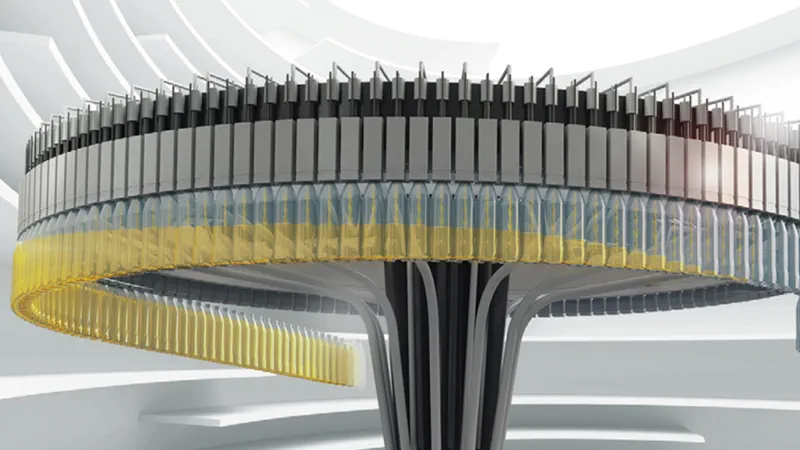

- Drinking Water Filtration

- Water Heaters

- Faucet & Fixture

- Press and Push to Connect Fittings

- Specialized Rubber Valves & Overmolded Seals

- Water Treatment

- Beverage Dispenser

- Powder and Bulk Material Handling Seals

- Pumps and Valves

- Water Irrigation

- Trelleborg FoodPro® Materials

- Food Grade Seals

- CIP and SIP

Learn more about water, food and beverage possibilities with Trelleborg Sealing Solutions, here.

Need help solving a tough engineering problem?

Case Studies

A More Durable Seal Reduces Warranty Claims for a Premium Water Softener Valve Manufacturer

A national manufacturer of premium water softener valves had been experiencing an increase in warranty claims from loyal owners. The company — a long-time Minnesota Rubber & Plastics customer — reached out to our engineering team to help them troubleshoot what was behind the warranty claims.

Tips for Designing Plastic Parts

When designing with plastic, the goal is to achieve a technically accurate design that functions well and can be cost effectively manufactured. Following these basic tips will help in accomplishing these goals and accelerate the designing process.

Other Resources

Approvals & Certifications for Potable Water and Sanitary