Applications

Our experience in manufacturing inflatable seals along with our unique molding technologies are well suited for the high performance requirements ofcommercial and military programs. These applications include a number of highly-customized naval and submarine sealing systems. Applications for our products include inflatable seals for sliding windows on Coast Guard vessels, large inflatable seals used for the aft deck ramp on Navy destroyers, and special inflatable butterfly valve seals used on Navy ships.

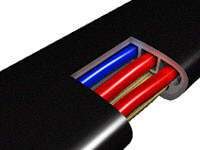

Aft Deck Inflatable Door Seals

We manufacture Type 1 inflatable seals using weather resistant EPDM rubber and silicone compounds. This seal is ideal for weathertight sliding doors and hatches exposed to the elements. Locations for these seals include patio doors, sundecks, aft-deck doors, and other leisure areas.