Applications

Sealing against dry particulates or chemicals can present many challenges. To ensure a positive seal, which can be maintained repeatedly, you need to have the right design and use the proper materials. We have extensive experience with powder and bulk material handling and our powder-handling seals are a perfect fit for many applications in this industry.

Hopper to Transfer Car Inflatable Seals

Inflatable seals are used on the mouth of a hopper valve or metering device; they are designed to expand axially down to form a leak-tight seal around the fill opening in a transfer cart. Type 1 style inflatable seals are best suited for this quick connect/disconnect application.

Inflatable Seals for Viscous Pumping Equipment

Type 10 style inflatable seals are an ideal solution for sealing around the periphery of follower plates when pumping viscous liquids, such as grease, paste, or cake frosting from their container drums. The rectangular profile of these seals minimizes the tendency of roll out from the seal’s retainer, which can pinch the seal when the follower plate descends.

Drum Filling Inflatable Seals

Type 1 and Type 2 style inflatable seals work particularly well for drum filling applications where the seal on the cover expands radially outward against the inside of the drum to allow for leak-tight filling.

Bulk Bag Filler Inflatable Seals

A filling equipment seal on the spout expands radially outward to effect a dust-tight seal against the inside of the bag neck during filling. This is very common with FIBC bulk bag filler systems. Any of the Type 1 or Type 2 styles of inflatable seals work very effectively in this application.

Mixer Lid Inflatable Seals with Square Corners

Inflatable seals can be configured with pre-molded 90 degree corners to effect leak-tight seals for hinged or sliding covers on access ways and other openings in mixers and other powder/bulk or fluid handling processing equipment. Type 1 style seals are best suited for this application.

Fluorosilicone Seals for Chemical Processing

Fluorosilicone is used to combat both high temperatures and aggressive chemicals. In this application, semi-conductor assemblies are treated in a large chemical bath. The fluorosilicone P-strip is used to seal the cover while the machine is operational.

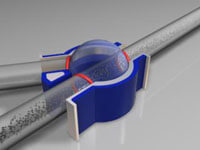

Inflatable Seals for Butterfly Valve

Inflatable seals are ideal for butterfly valves in tight sealing applications. The clearance between the deflated seal allows for low torque rotation of the disk and eliminates the damaging effect of abrasion on the seal. When the disk is fully closed, the seal inflates radially inward against its edge to effect a leak-free condition.

Slide Gate Valve Inflatable Seals

Inflatable seals provide the tightest seal possible for controlling the flow of very fine materials. The valve seal does not inflate until the blade is firmly in position and then the seal inflates – creating a leak-free seal.

Inflatable Seals for Rotary Union Ports

Ports and passages through rotary valves are readily sealed leak tight with inflatable seals. The seals can be located in glands machined in the valve body to expand inward against the plug or they can be located in glands machined in the plug to expand outward against the valve body. When deflated, the plug can be rotated with minimum torque since there is no seal frictional force to overcome. When inflated, a tight seal forms to control the direct flow of the fluid or solid material.