Application

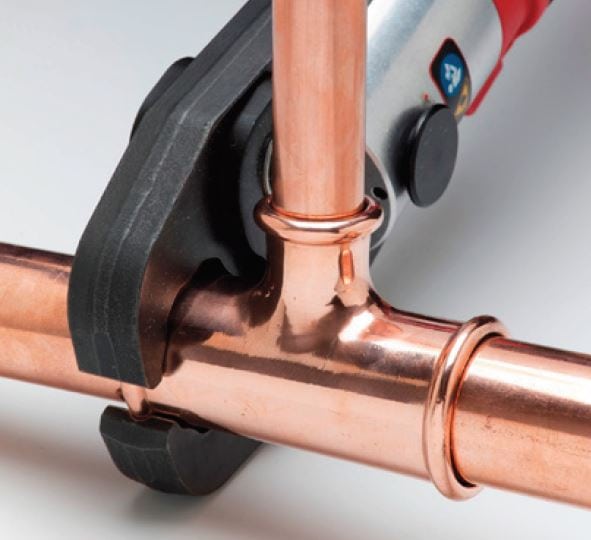

Press and Push to connect fittings are faster to install, safer and require less training than traditional soldered connectors. Press and Push to connect fittings require high quality, custom designed o-rings that will last for 50 years or more. MRP is a leader in formulating and designing these high-performance rubber seals.

Benefits

Minnesota Rubber and Plastics rubber formulations are designed to meet global regulations while still being highly chemical and compression set resistant. MRP was one of the first rubber manufacturers to provide the industry with chlorine and chloramine resistance compounds. Through continuous improvement, the latest compounds have even higher levels of chlorine and chloramine resistance.

Our rich history as a leader in the water market means we can solve your fitting seal challenges quickly and efficiently with the latest technology.

Extensive qualification is completed in our NSF audited lean six sigma production facilities. Automated vision inspection ensures that each and every part will seal reliably.