Case Study

New Material Formulation Leads to Seal for Point-of-Care Diagnostics

Rapid response to urgent COVID-19 patient needs with a seal that meets strict chemical and mechanical requirements.

Challenge

Design a seal for a point-of-care (POC) test that tolerates extended chemical exposure.

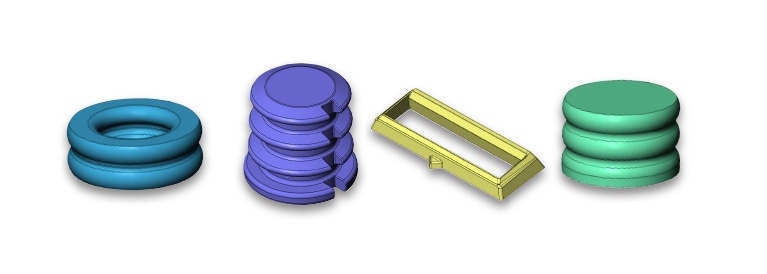

POC tests are often used to rapidly diagnose infectious diseases like COVID-19. They provide results within minutes, enabling health care professionals to make quick decisions regarding patient care. The POC test uses a seal to control the release of reagent during operation, eliminating the need for complex fluid handling systems.

An existing Minnesota Rubber & Plastics customer was developing a new POC test device. The material they were using for their seal was breaking down when exposed to their proprietary chemical reagent and was unable to meet the product’s long-term aging requirement. Not only that, but the seal was also failing to withstand the mechanical stresses placed upon it during operation.

The customer turned to our experts to redesign their seal geometry with a new compound formulation that would be compatible with their reagent and meet the mechanical needs of their testing cycle.

Solution

A custom formulation and seal geometry that withstands chemical and mechanical stress.

The Minnesota Rubber & Plastics Advanced Material Group (AMG) began work by finding an existing formulation that closely matched the requirements of the customer’s application. With over 1,000 proprietary compounds in the AMG library, they were able to immediately accelerate the project by quickly finding a compound that closely met the customer’s needs.

Using the library formulation as a base, a custom compound was developed that was highly resistant to the chemistry of the customer’s proprietary reagent. The AMG team’s experience with the unique challenges of diagnostic reagent chemistry helped ensure a smooth development process. The team’s internal testing capabilities were put to work, subjecting the new compound to a battery of tests and failure analysis to help find the right formulation and durometer for the customer.

With the new compound in hand, the customer’s seal geometry was redesigned to handle the mechanical stress of the device in operation. Taking it a step further, a second compound was developed by the AMG team to further optimize the seal performance. This second compound improved ease of assembly and long-term wear while reducing friction within the device’s prefilled chamber.

Results

A seal that satisfied the customer’s needs, improving patients’ lives in the US and EU, and responds to the COVID-19 Pandemic.

Leveraging the AMG formulation library, along with the team’s development and testing capabilities, Minnesota Rubber & Plastics delivered a solution that surpassed customer expectations on functionality, delivery, and financial value.

The new compound and seal geometry easily withstood the customer’s reagent and the mechanical stresses placed on it during operation. The customer would go on to secure emergency use authorization (EUA) and later CE Mark approval for their device. The device is currently used as a diagnostic device for COVID-19 detection, and for other infectious disease applications.

Print-Ready Case Study

Download this diagnostics case study in PDF format.