Core Services

We specialize in developing and manufacturing custom-molded rubber and thermoplastic components, and the integration of both into complex assemblies.

We pride ourselves on our ability to provide value-added services during the early stages of your rubber or plastic component development program. From material development and selection to product design and manufacturability, we want to be your development partner.

Material Science & Formulation

Minnesota Rubber and Plastics has been a global leader in advanced rubber material formulation for over 75 years.

Our custom compounds have solved some of the world’s toughest sealing challenges in the medical, water, food and beverage markets. We understand the difference the right material can make in your application, that’s why we have one of the best teams in the industry dedicated to assisting you.

Product Design & Development

We have dedicated and highly experienced Product Design Engineers that are ready to collaborate with you on providing product design Assistance to ensure successful and timely launch of your differentiated sealing solution.

Our engineers conceptualize and evaluate ideas by combining science and technology to create value. Their development role is facilitated by digital tools, including non-linear FEA, that allow them to visualize and analyze new designs, materials and products.

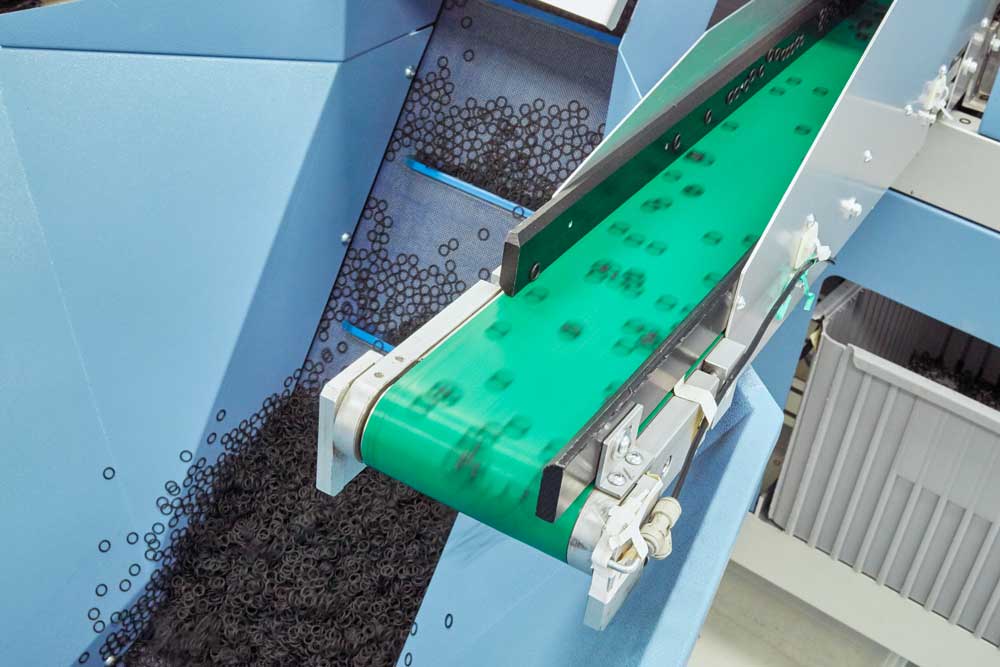

Manufacturing & Testing

In complement to our expertise in material development and product design, we also have state of the art operations around the globe utilizing the most advanced molding process and techniques.

We specialize in injection molding, transfer molding, compression molding and over-molding on the most advanced equipment available.