Technical Capabilities & Tools

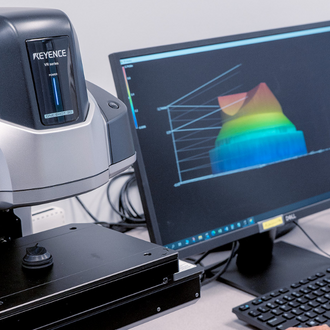

Materials Science Tools

Materials science is at the heart of any new product we develop. Here are some of the tools we use to formulate, evaluate & select materials:

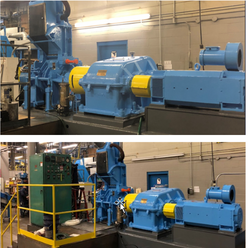

Farrel 16-liter

Banbury Internal Mixer

This small volume mixer enables rapid compounding of custom and standard materials; An integral step of process development, moving from formulation design to production process development and scale up.

Stewart Bolling Laboratory Mill

This 2-roll milling machine helps us in the early stages of mixing materials as we try new compounds.

Differential Scanning Calorimeter

A DSC can determine the glass transition temperature of a material to assess viscoelastic performance across specified temperature ranges in an application

Rubber Process Analyzer

A RPA identifies the cure kinetics and rheology of a compound from which AMG specialists use to provide process recommendations and suitable manufacturing methods.

Materials Library

Our proprietary library of 1,000s of material compounds allows our Advanced Materials Group (AMG) to identify existing materials that meet requirements, thus reducing development time.

Dynamic Mechanical Analyzer

The DMA measures the viscoelastic behavior at different frequency and temperature to determine storage modulus, loss modulus, tan delta and glass transition temperature.

Tensometer

A Tensometer measures tensile strength, ultimate elongation, modulus, tear resistance, and bond strength (adhesion). It is typically used for quality control, material development and production testing.

Infrared Spectroscopy

FTIR analysis provides information for chemical characterization of rubber polymers, plastics and other raw materials.

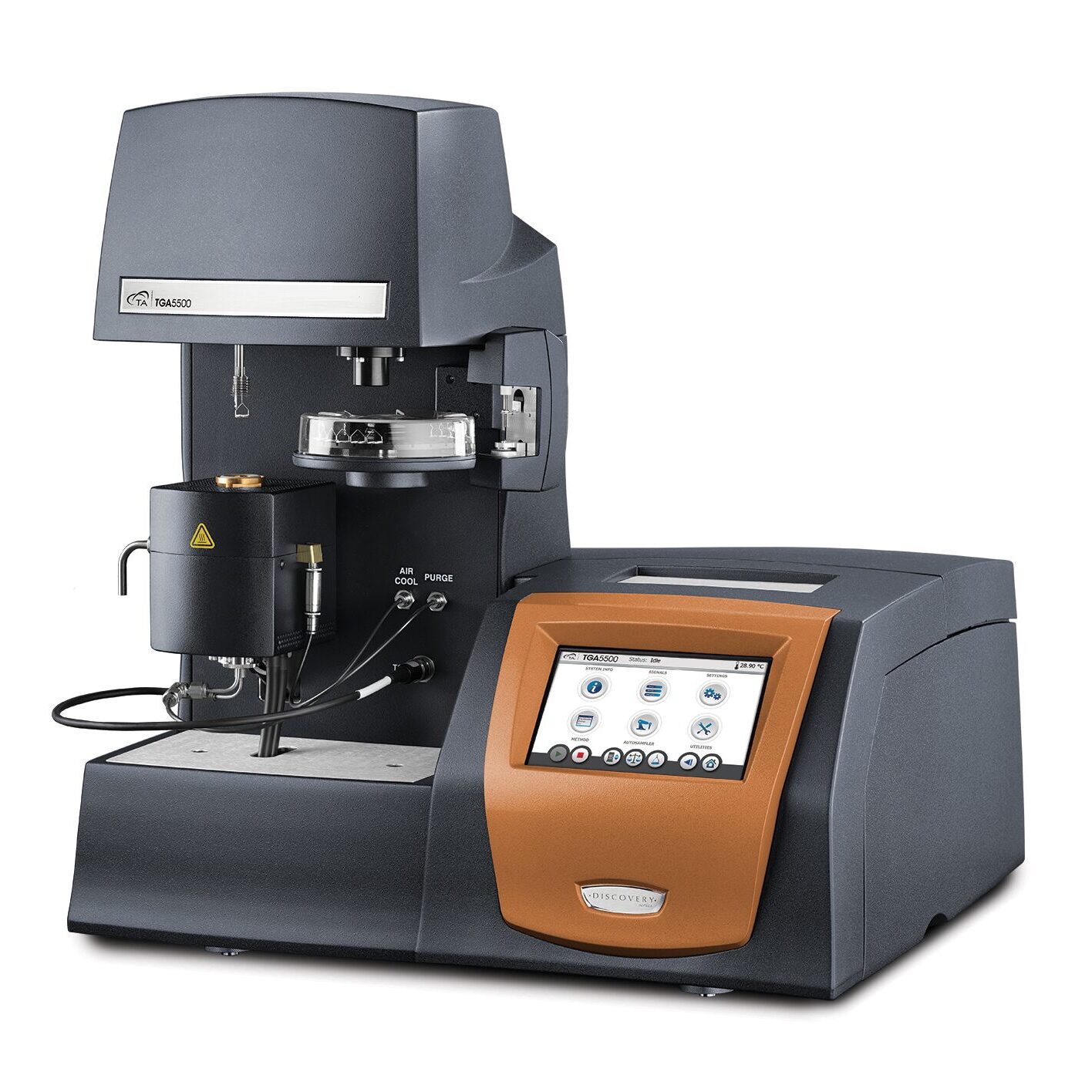

Thermogravimetric Analyzer

Thermogravimetric Analysis (TGA) measures compositional ratios of components in rubber and plastic and characterizes thermal stability of polymers and other raw materials in support of development and investigation activities.

Component Design

Our design engineers work closely with our materials scientists (and you) to explore the best fit. These are some of the tools we use for component analysis:

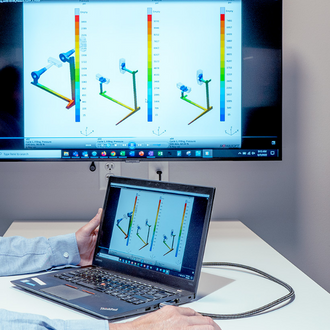

Finite Element Analysis

FEA software uses best-in-class 3D analysis to predict how a set component reacts to real-world forces including vibration, heat, fluid flow, and other conditions your product will endure.

Mold Flow Analysis

MFA simulates how the material will flow into the production mold. We tinker with the model, adjusting the gate and vents to ensure consistent success when manufactured at scale.

Design For Manufacturing

DFM analysis is an integral philosophy of our entire design process. Our design engineers conduct multiple analyses to ensure the quality of components produced at any of our plants.

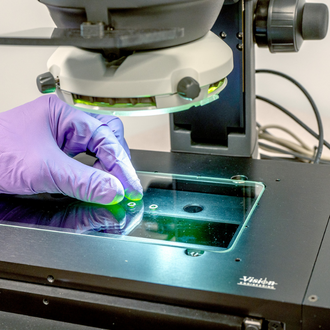

Prototype Tooling & Equipment

A highlight of our Innovation Center is accelerated in-house tooling production and equipment:

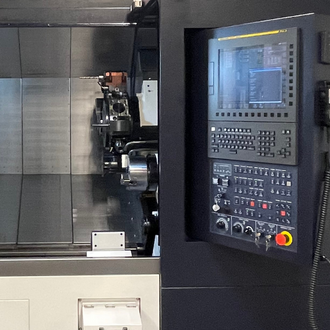

YSMC LATHE

New Mill Turn Machine with turning and milling capability gives us many options

High-Speed Mill

Ultra-accurate mill manipulates materials within .00001” in any shape.

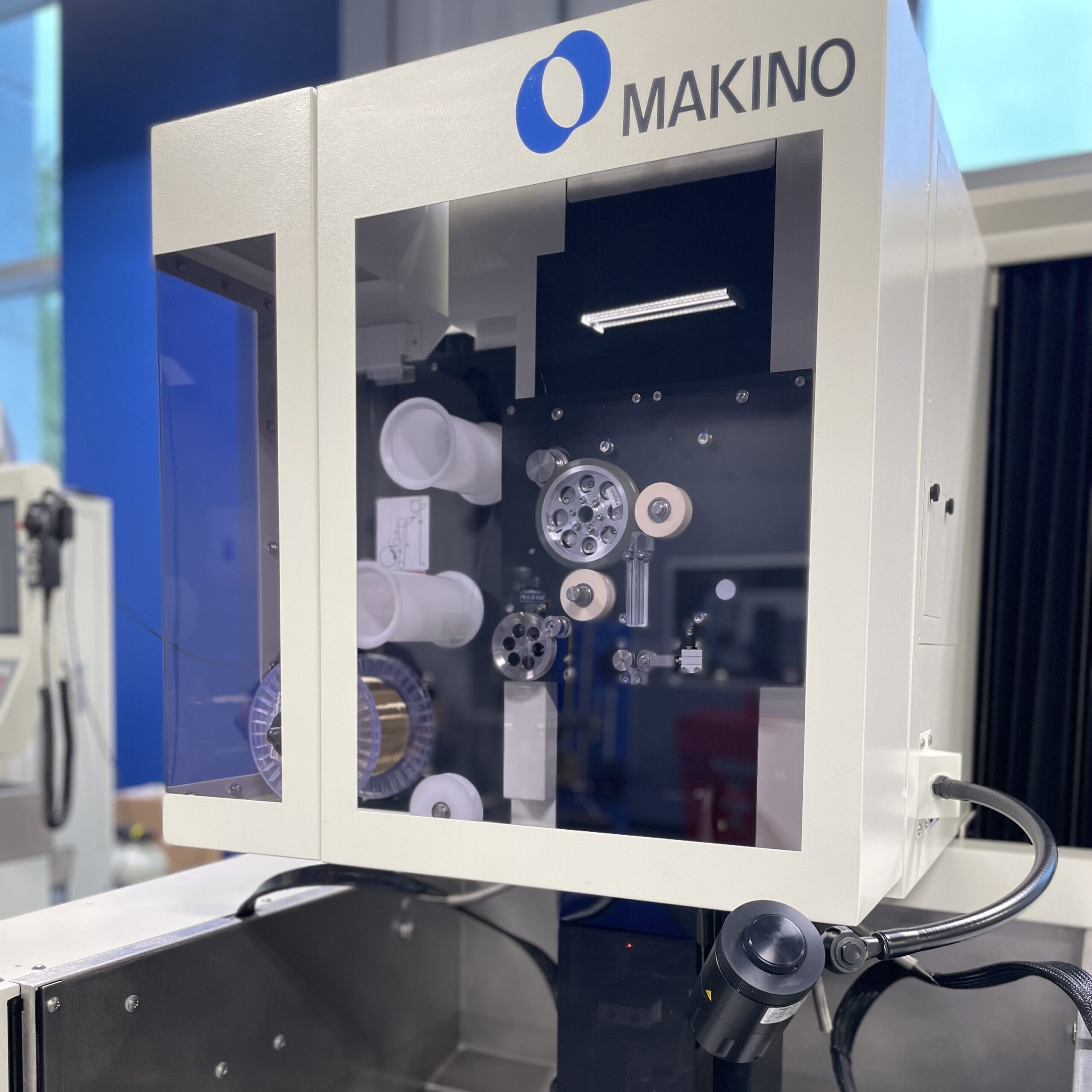

Wire EDM

An electrically charged wire cuts the entire thickness of a steel piece from top to bottom, in any shape.

EDM Drill

Advanced drill provides a precise starting point for the wire EDM to begin its work.

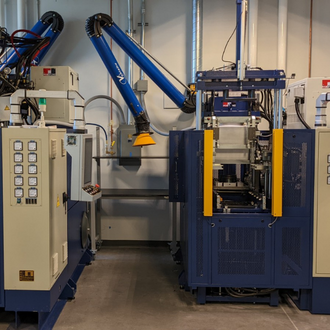

Prototype Presses

These new, state-of-the-art, presses are identical to systems on our manufacturing floor, only with smaller footprints. A mirrored prototyping process allows our veteran process engineers with specialized material experience to create detailed production blueprints for our global manufacturing facilities.

Liquid Silicone Rubber Engel 30T Horizontal

The precise metering and shot control of this press allows us to produce Liquid Silicone prototypes with the utmost precision. The press has been augmented with a robot in order to allow for fully automated processing and part handling.

Elastomer Pantsone 50T

These vertical injection and transfer presses provide the ultimate in elastomer manufacturing flexibility and precise process controls, allowing both individual component and overmolding of complex geometries in a variety of manufacturing processes.

Elastomer Engel 110T Horizontal

This press has been purposefully built with flexibility and precision in mind. The press combines the latest in elastomer processing technology and material feed flexibility to injection mold a vast array of elastomers (EPDM, FKM, IIR, HCR) in a fully automated format.

Plastic Injection Arburg 28T Vertical

This machine utilizes a rotary table to reliably produce high quality plastic prototype samples. The rotary table allows for both simultaneous molding (shorter cycles) and overmolding of complex products containing inserts.