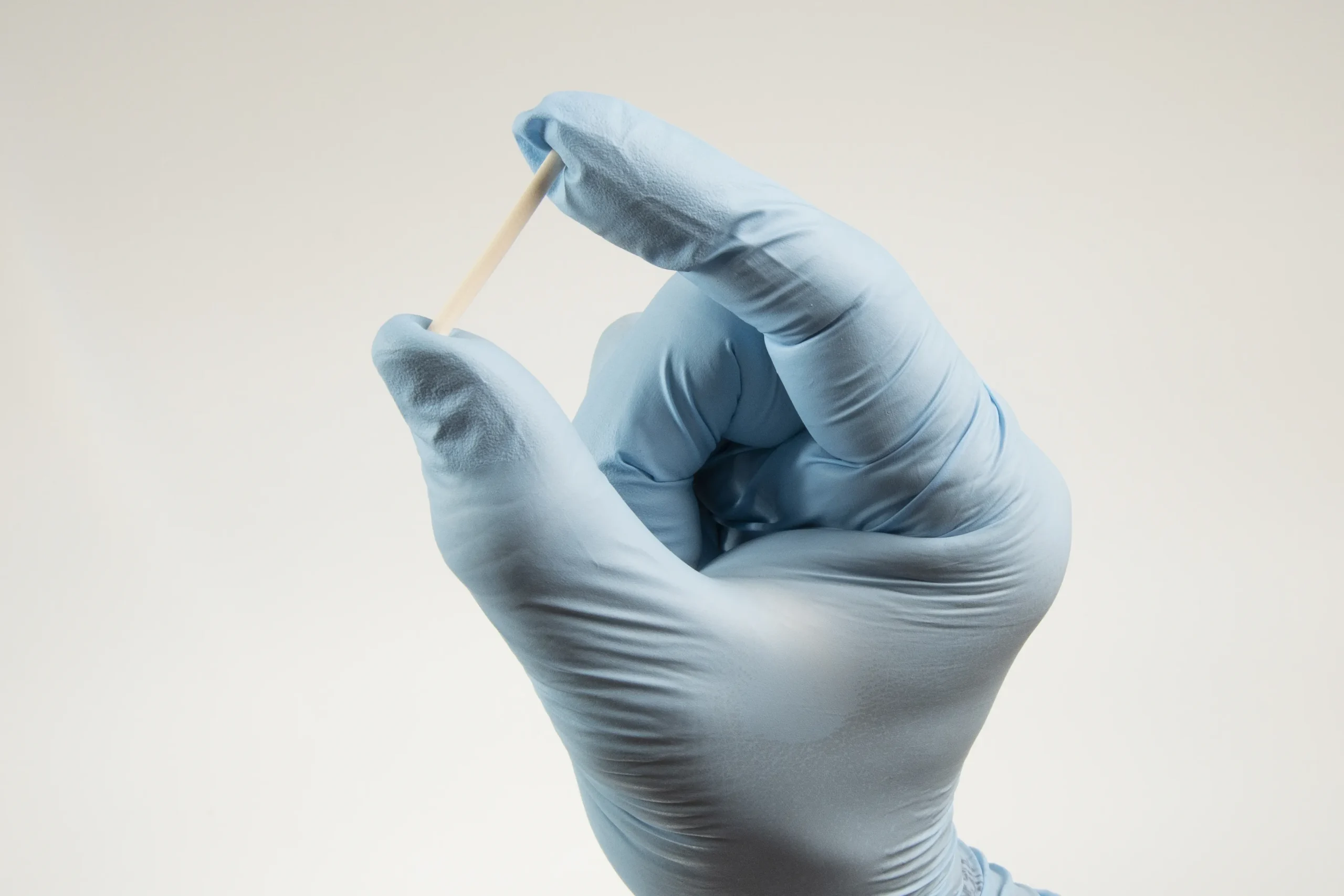

Expertise in combining polymers with active pharmaceutical ingredients (APIs) to produce implantable drug delivery systems and combination devices.

Whether enhancing a device by adding anti-inflammatory compounds or delivering pharmaceuticals via a controlled drug delivery system, Trelleborg can provide targeted delivery solutions that significantly improve patient quality of life.

Technological advancements in controlled drug delivery products offer medical device manufacturers and pharmaceutical companies the opportunity to develop smaller, less invasive, and more effective products. Silicone materials provide many advantages and are commonly used in drug delivery applications, while alternative polymer excipients can also provide distinct advantages based on desired outcomes for the therapy being developed.

Applications

- Women’s Health

- Ocular Drug Delivery Systems

- Cancer Treatment

- Wound Care

- Steroidal Collars

- Pacemaker Leads

Silicone is extremely versatile and delivers unmatched biocompatibility, making ideal for use in a broad range of applications, including targeted and controlled-release drug delivery systems.

Resources

Whitepaper

This whitepaper reviews the methods for introducing an API to raw silicone and explores a new means of formulation, with test results proving the effectiveness of each.

Introducing APIs to silicone & controlling elution rates webinar

This webinar takes a deep-dive into the manufacturing methods used to produce implantable drug delivery systems and combination products and includes details on patient impact, use cases, market outlook while covering several case studies.

Podcast

With pharma’s focus on the extension of drug release windows, new technologies are needed to lengthen that duration. This podcast offers insights into how long acting implantables and polymeric drug delivery can address that need.

Implantable drug delivery webinar

This webinar gives an overview of implantable drug delivery systems. It explores use cases in the market today, market trends, manufacturing considerations and methods of formulation.

Introducing APIs to Silicone

Adding an API to Raw Silicone

Introducing an API into silicone usually involves the combination of Liquid Silicone Rubber (LSR) with an API before fabrication into a silicone part. The API combines with both parts of the raw silicone just before manufacturing it into its final form via extrusion, molding, or sheeting processes.

Impregnating Vulcanized Silicone with an API

Another method of introducing an active pharmaceutical ingredient to silicone is to immerse a finished silicone part in a drug-loaded solvent, which causes swelling and allows the API to impregnate the silicone matrix.

Membrane-Controlled Elution Rates

Using a silicone membrane also enables manufacturers to control the elution rate. A commonly used method is to apply a membrane, such as an extruded silicone tube, to a drug-loaded core to modulate its release profile.

Advantages of API Elution

- Controlled release of an API enables a consistent concentration of the drug, in contrast to bolus-style delivery which fluctuates within the therapeutic range.

- Implanted targeted drug delivery systems can provide a targeted release of pharmaceutical ingredients to a specific site within the body.

- As opposed to systemic administration, controlled drug delivery systems allow for longer-term dosages while minimizing adverse side effects.

- Combination products can offer significant advantages when patient compliance is a high-risk element of other existing therapies on the market.

- Patient’s quality of life can be improved by minimizing the effort they have to put in to manage a condition that is particularly high maintenance.

- Lowered dosage requirements may be possible through targeted drug delivery systems.

- Simplified treatment regimens lead to fewer visits to the practitioner, relieving the strain on health services.