FoodPro® Materials

High Performance elastomer and plastic material range to meet the unique needs of the food and beverage industry.

The Trelleborg Sealing Solutions FoodPro® range is a comprehensive portfolio of polymer-based materials specifically designed to meet the unique requirements of the food and beverage industry. Alongside FoodPro®, a number of other materials from our standard range can be used in food contact applications. Implementation of Good Manufacturing Practice (GMP) ensures the ultimate in production efficiency and safety.

The FoodPro® material range is a continuously expanding portfolio of materials, specially designed to meet the needs of the food and beverage industry. The range includes standard elastomers like EPDM, NBR and FKM, Isolast® FFKM and respective plastics Turcon® PTFE and Zurcon® Poly Ethylene. FoodPro® materials are available for standard and custom-designed seals, bearings and components across the globe. Local Trelleborg Sealing Solutions engineers support with seal design to meet hygienic design requirements.

Learn more about seals and sealing components

Material compatibility and cleanability are paramount

The sealing environment within food and beverage processing is perhaps the most demanding of all. Seal failure can lead to potential contamination or line stoppages. Materials, whether elastomer or plastics, have to cope with a broad variety of food types along with Cleaning in Place (CIP) and Sterilization in Place (SIP). FoodPro® materials offer proven high sealing performance and are suitable for CIP and SIP processes used in the food industry.

Compliance with regulatory requirements

Sealing materials must also be compliant with food contact material regulations in different countries. FoodPro® materials comply with the most relevant food contact regulations globally such as the U.S. Food and Drug Administration (FDA) regulations, European Food Contact Regulations including Reg. (EC) 1935/2004, Chinese food safety standards and the Japanese Positive List released in 2020.

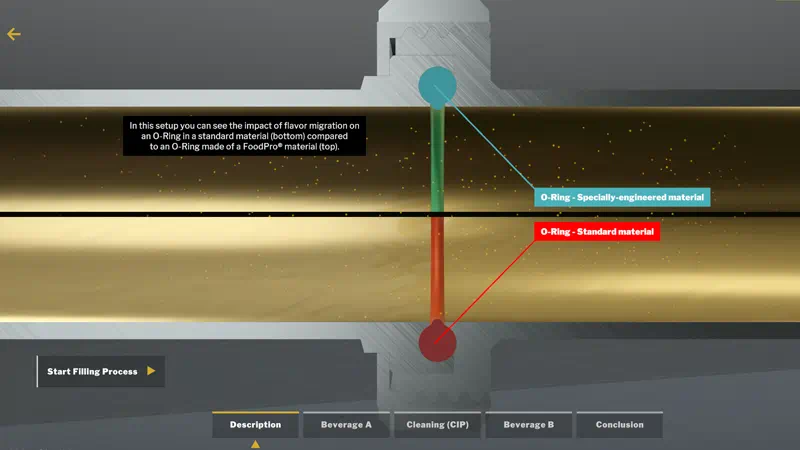

Virtual Showroom

The FoodPro® Materials exhibit demonstrates how specially engineered materials minimize flavor carryover reducing water consumption and costs for beverage bottlers.

Tools & Resources

Skol to a Sustainable Beer

A partnership with Dalum Beverage Equipment enables sustainable craft beer brewing.

FoodPro® EPDMs

This revolutionary, new family of EPDM materials is specifically designed to meet the unique requirements of the food and beverage industry.

EPDM

Industry specific compounds meet application requirements

Industry specific compounds meet application requirements

Ethylene Propylene Diene Rubber (EPDM) polymers are fully saturated, unpolar hydrocarbon-based elastomers. Their polymer geometry gives them superior compatibility with polar fluids even at elevated temperatures.

The materials demonstrate:

- High chemical resistance

- Long life in polar solvents, hot water and steam

- Suitability with alkaline and acidic cleaners

- Excellent choice in most dairy applications, except for products with high fat content

Products:

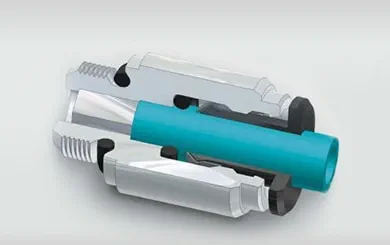

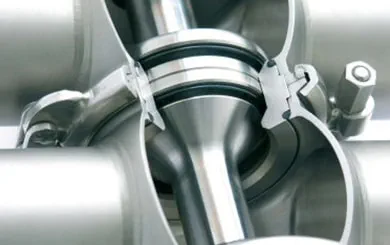

O-Ring, Kantseal square rings, FlatSealTM, Gaskets, Diaphragms, also reinforced. EPDM can also be bonded to other materials and delivered as engineered parts in almost any design.

Applications:

Used in almost all types of applications as a universal material, suitable both in cleaning and sterilization processes (CIP/ SIP).

Typical applications are filling, dispensing, pumps, pipe and flange gaskets, valves, quick connectors, tanks,separators, homogenizers, decanters and heat exchangers.

NBR

Excellent performance in contact with fatty foods

Acrylonitrile-Butadiene Rubber (NBR) is a good choice for applications where seals will not be exposed to harsh cleaning regimes, ozone or superheated steam. These materials are copolymers of butadiene and acrylonitrile.

The percentage of these in the NBR formulation determines their performance characteristics.

NBR materials demonstrate:

- Good mechanical properties

- Suitability for long-term operating temperatures from -30°C to +100°C / -22°F to +212°F and up to 120°C / 248°F for short periods

- Excellent performance in animal and vegetable fats and oils, therefore ideal for meat and poultry processing

FKM

FKM optimized for steam environments

Trelleborg Sealing Solutions has optimized the performance of our Fluoroelastomer (FKM) material range, to meet the specific criteria of the processing industry.

FKM materials demonstrate:

- Good elevated temperature characteristics

- Very good suitability for use in contact with vegetable oil and fat, animal fat and high fat dairy products

- Good compatibility with most CIP media and SIP conditions and lubricants

- Good resistance against ozone and aging

Products:

O-Ring, Kantseal square rings, FlatSealTM, Gaskets, Diaphragms,also reinforced. FKM can also be bonded to other materials and delivered as engineered parts in almost any design.

Areas of use:

Especially suited for processes involving contact with high fat media such as grease and oils or at high temperature.

Typical applications include Mechanical Seals, Decanters, Separators, Pumps, Tanks, Valves, including mix proof valves, Heat Exchangers and equipment cleaned using CIP and SIP regimes.

Silicone and Liquid Silicone Rubber

Silicone inherently inert to growth of bacteria, mold and fungi

Silicone materials are ideal for use in food and beverage production due to their inherent inertness to growth of bacteria, mold and fungi.

Advantages of silicone:

- Excellent heat resistance, cold flexibility and dielectric properties

- Preferred choice in applications exposed to ozone and oxygen

- Operating temperature from -60°C to +200°C / -76°F to +392°F

- Exceptionally low surface energy, seals will not adhere to counterparts.

- Low long-term compression set

- Suitable for use with hot water, fat and oil, some lubricants and glycerin.

A possible limitation of silicone is that chemical degradation can occur in contact with acids, alkalis, ketones, esters and steam above 100°C / 212°F.

Turcon® PTFE

Engineered for demanding applications

Turcon® is the Trelleborg Sealing Solutions brand of proprietary Polytetrafluoroethylene (PTFE) based compounds.

Turcon® offers:

- Excellent friction and self-lubricating characteristics

- Suitability for dynamic and rotating applications, including those with abrasive media and countersurfaces

- Outstanding performance in low and high temperature environments

- Compatibility with almost all chemicals

Turcon® FoodPro® MF designed for processing needs

Turcon® FoodPro® MF1, MF2, MF3 and MF6 have been formulated to meet special requirements of the food and beverage processing industries. Based on ultra-clean technology, these compounds are manufactured from high-purity PTFE grades and additives. Their smooth finish, with high gloss and low porosity, avoids the risk of contamination buildup and reduces particle shedding.

Turcon® FoodPro® compounds are particularly suitable for use in CIP and SIP processes due to its high operating temperatures and media resistance.

Applications:

- Multipurpose equipment with mixed process streams, where seals are exposed to extremely aggressive cleaning solvents

- Filling machines: Turcon® Variseal® eliminates contamination

- Coffee machines: high abrasion resistance and low friction

HMF48

Flat gasket material for food contact applications

Formulated from virgin polytetrafluoroethylene (PTFE) and enhanced with high-quality approved fillers, the new HMF48 material offers a ‘universal’ solution for food and beverage processing.

HMF48 demonstrates:

- Compliance with global food contact regulations, including FDA, EU and Chinese GB guidelines

- Compatible with process chemicals

- Suitable for use under a wide range of temperatures -210°C to +260°C/-346 °F to +500 °F

- Pressure resistance from vacuum up to 83 bar

- Universal applicability enables standardization of many different types of seals

- Wide range of thickness and sheet formats available to enable simple and inexpensive production of almost any seal geometry

- Gaskets characteristics in accordance with DIN EN 13555, allowing design of permanent tight flange connections

- Availability of all important gasket constants allows safe seal designs and calculation

- Unlimited shelf life

Zurcon® Engineered Plastic

Engineered plastic based material for reciprocating and oscillating situations

Zurcon® is the brand name for the Trelleborg Sealing Solutions range of engineered plastic based materials, including PEEK and UHMWPE.

Zurcon® FoodPro® Z81

Zurcon® FoodPro® is ideal for reciprocating, very slow rotating and oscillating applications, where high wear resistance is required, including applications with abrasive media and countersurfaces. The material is ideal for a variety of food processing applications, such as filling machines, valves, pumps, mixers, separators, homogenizers, centrifuges, dosage cylinders, and sensors.