Literature & Resources

Brochures

Case Studies

Developing a Custom Material for Trocar Seal Surgical Applications

The elastomer material for a customer’s new trocar surgical application was catching on material during insertion, often tearing the seal. They turned to our advanced materials group (AMG) team to create a material that solved this primary concern. See how our AMG team solved the problem and helped to make the trocar a superior solution for physicians.

New Material Formulation Leads to Seal for Point-of-Care Diagnostics

Our team was part of the rapid response to urgent COVID-19 patient needs. We created a new material formulation for a point-of-care medical diagnostics seal that meets strict chemical and mechanical requirements.

Custom Formulated Material Delivers High Performance for a Surgical Seal Solution

A large medical technology company aimed to upgrade its medical device solution used primarily to cut and cauterize tissue in minimally invasive surgeries. The goal was to improve the design to allow surgeons to reuse the device by creating a disposable biocompatible flexible sleeve cover for the surgical instrument.

Wilson Wolf G-Rex® Gas Permeable Cell Culture Device Molded And Assembled By Minnesota Rubber And Plastics

Wilson Wolf created a paradigm shift with its cell culture design disrupting age-old beliefs regarding cell production. Minnesota Rubber and Plastics (MR&P) facilitated the unique design with an efficient, high quality molded, assembled and packaged G-Rex branded product ready for the medical marketplace.

Medical Device Sealing Solutions

What designers and manufacturers need to know, avoid and consider when planning seals in a medical device.

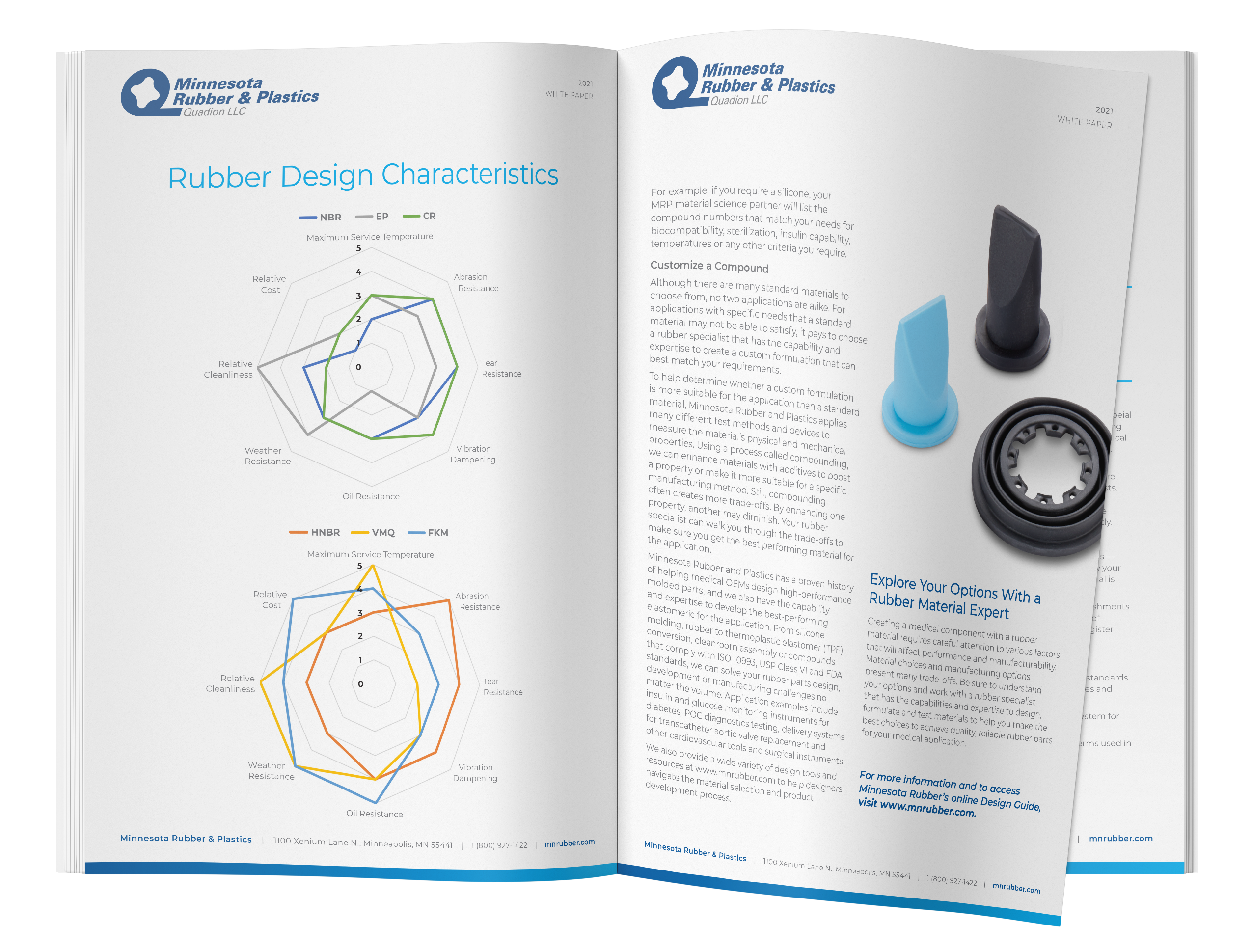

Medical Selection Guide: Choosing the Right Rubber Material and Process for Your Medical Parts

When it comes to selecting the right rubber material for your medical device, understanding your application, the physical and mechanical properties of your material options and the interaction with mating components will go a long way.

Formulated for an Era of New Challenges: Elastomer Material Flexibility Optimizes Performance and Meets New Challenges

Did you know? Custom black rubber is often a valid material option in the medical device manufacturing industry.

Other Resources

Medical Market Quality & Environmental Certifications

Trelleborg Healthcare & Medical Whitepapers & Technical Articles