Quad-Ring® Brand Rotary Seal Application

Sealing Systems for the Rotary Application

Quad-Ring® Brand Seals (standard and custom molded)

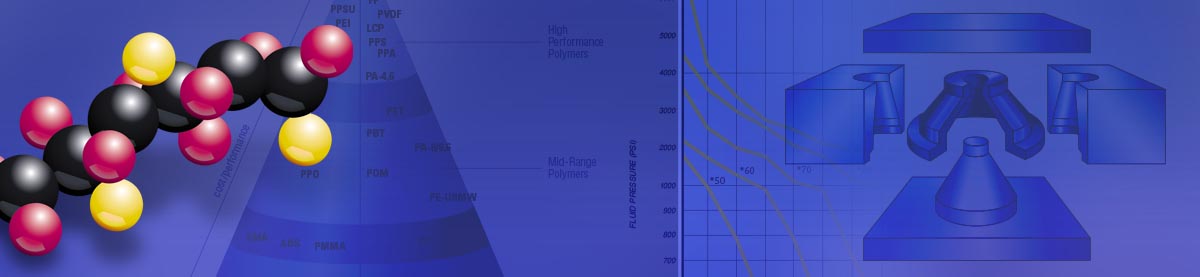

If applied correctly, standard Quad-Ring® Brand seals can be excellent rotary seals as compared to more expensive alternatives. They offer low friction for long life in hydraulic systems with speeds up to 900 FPM (4.5 M/Sec) and a maximum pressure of 750 psi (52 bar). Refer to this table for correct sizing of Quad-Ring® Brand seals for your application.

Modified Quad-Ring® Brand Seals (custom molded)

This modified Quad-Ring® Brand seal has a deeper valley than the original Quad-Ring® Brand seal design, thereby producing lower deflection force value and reduced friction. Using Modified Quad-Ring® Brand seals will extend the seal life of rotary applications with pressures less than 100 psi.

Quad-Kup® Brand Seals (custom molded)

For high diametrical clearance applications and those requiring low operating friction. Provides low-pressure seal up to 150 psi (10.3 bar) in reciprocating and rotary applications. The combination lobed/cup configuration can be designed with the lip on any of the four surfaces, top or bottom, on the ID or OD.

Quad® P.E Plus Brand Seals (custom molded)

This dual-function seal forms a self-lubricating seal and an elastomeric spring for both rotary and reciprocating applications. Newly patented, this seal design combines injection moldable thermoplastic bearing material with a Quad-Ring® Brand seal. This seal is not intended for zero leakage applications.

Specialized Seals for Demanding Applications

Each rotary application is unique, often involving media other than oil or extreme conditions of temperature, pressure, or friction. Special seals are available to meet these demanding requirements.